I-Hot dip galvanizing, eyaziwa ngokuba yi-galvanizing, yindlela yokuntywilisela amacandelo entsimbi kwi-zinc etyhidiweyo ukufumana i-coating yensimbi.isebenzisa i-electrochemistry, isebenzisa i-zinc ingot njenge-anode.I-athomu ye-zinc ilahlekelwa yi-electron kwaye ibe yi-ion kwaye ichithe kwi-electrolyte, ngelixa izinto zensimbi zisebenza njenge-anode.Kwi-cathode, ii-ion ze-zinc zifumana i-electron kwintsimbi kwaye zincitshiswe kwii-athomu ze-zinc ezifakwe kumphezulu wentsimbi ukuphumeza inkqubo apho i-coating yenza iyunifomu, i-dense, kunye ne-bonding metal or alloy deposition layer. Eli nqaku liza kukunika inkcazo enzulu yomahluko phakathi kwezi zimbini.

1. Ubunzima bokwaleka obahlukeneyo

Idiphu eshushu yokwaleka eyenziwe ngamazinki inomaleko ongqindilili we-zinc, malunga ne-40 μm okanye ngaphezulu, okanye nokuba phezulu ukuya kuma-200 μm okanye ngaphezulu.Umaleko wediphu oshushu ngokuqhelekileyo uli-10 ukuya kwangama-20 kunomaleko we-zinc ofakwe i-electroplated.I-electroplated zinc coating incinci kakhulu, malunga ne-3-15μm, kwaye ubunzima bokugquma bu-10-50g / m2 kuphela.

2. Izixa ezahlukeneyo zokugalela

Isixa sokugalela iikhoyili zentsimbi ezifakwe emanzini ashushu azinakuba ncinci kakhulu.Ngokuqhelekileyo, ubuncinci bungama-50 ~ 60g / m2 kumacala omabini kwaye ubuninzi bungama-600g/m2.Uluhlu lwe-galvanized ye-electro galvanized steel coil lunokuba luncinci kakhulu, kunye nobuncinci be-15g / m2.Nangona kunjalo, ukuba i-coating iyadingeka ukuba ibe nkulu, isantya somgca wemveliso siya kucotha kakhulu, esingafanelekanga kwiimpawu zenkqubo yeeyunithi zanamhlanje.Ngokuqhelekileyo, ubuninzi bungama-100g/m2.Ngenxa yoko, ukuveliswa kweentsimbi ze-electro galvanized steel sheets kuthintelwe kakhulu.

3. Isakhiwo sokugquma sihluke

Kukho umaleko wekhompawundi ofuthe kancinci phakathi kwezinki ecocekileyo yokwaleka yediphu eshushu yamaphepha kunye nepleyiti yentsimbi.Xa i-zinc ecocekileyo igubungele i-crystallizes, ininzi yeentyantyambo ze-zinc zenziwe, kwaye i-coating ifana kwaye ayinayo i-pores.Ii-athomu ze-zinc kwi-electroplated zinc layer zichithwa kuphela kumphezulu weplate yensimbi, kwaye zifakwe ngokwasemzimbeni kumphezulu wentsimbi yentsimbi.Kukho iipores ezininzi, ezinokubangela ngokulula ukubola kwemigodi ngenxa yemithombo yeendaba ezonakalisayo.Ke ngoko, iipleyiti zediphu ezishushu zixhathisa ngakumbi kune-electro galvanized plates corrosion.

4. Iinkqubo ezahlukeneyo zonyango lokushisa

Amashiti entsimbi aditshiweyo ashushu enziwe ngeepleyiti eziqinileyo ezibandayo kwaye ahlala ehlala e-annelled kwaye idiphu eshushu igalelwe kwintambo yokufaka igalvanizing.Intsimbi yentsimbi ifudunyezwa ixesha elifutshane kwaye ipholile, ngoko amandla kunye neplastiki ichaphazeleka kwinqanaba elithile.Ukusebenza kwayo kwesitampu kubhetele kunokuba Ipleyiti enzima ebandayo efanayo yahlukile kwipleyiti yentsimbi eqengqelekayo ebandayo emva kokuthotywa kwegrisi kunye ne-annealing kumgca wemveliso yobungcali.Amaphepha entsimbi aditshiweyo ashushu aneendleko eziphantsi zemveliso kunye noluhlu olubanzi lwezicelo, kwaye ziye zaba zezona ntlobo ziphambili kwimarike yamaphepha enziwe ngamagalvanized.I-Electro galvanized sheet sheets isebenzisa amacwecwe entsimbi abandayo njengezinto eziluhlaza, eziqinisekisa ngokusisiseko ukusebenza okufanayo kwamaphepha aqengqelekayo abandayo, kodwa inkqubo yayo entsonkothileyo ikwanyusa iindleko zemveliso.

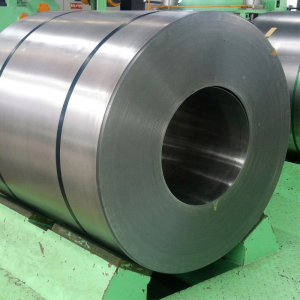

5. Imbonakalo eyahlukileyo

Umphezulu wediphu eshushu i-galvanized layer ilukhuni kwaye ikhanya, kwaye kwiimeko ezinzima kukho iintyatyambo ze-zinc;i-electro galvanized layer igudileyo kwaye ingwevu (ibala).

6. Imida eyahlukeneyo yesicelo kunye neenkqubo

I-Hot-dip galvanizing ifanelekile kumacandelo amakhulu kunye nezixhobo;i-hot-dip galvanizing kukuchola umbhobho wentsimbi kuqala.Ukuze kususwe i-iron oxide ebusweni bombhobho wensimbi, emva kokukhetha, idlula i-ammonium chloride okanye i-zinc chloride isisombululo se-aqueous okanye i-ammonium chloride kunye ne-chlorine.I-Zinc ixutywe itanki yesisombululo esinamanzi sokucoca, kwaye emva koko ithunyelwe kwitanki yokucoca idiphu eshushu.

Ikhoyili yentsimbi editshiweyo eshushu inokhuselo oluhle, ityabeka eshinyeneyo, kwaye ayidibanisi nobumdaka.Ineenzuzo zokugquma okufanayo, ukunamathela okuqinileyo kunye nobomi obude benkonzo.I-Hot-dip galvanizing inokumelana ngcono nokuhlwa kwe-atmospheri yentsimbi esisiseko kune-electro-galvanizing.

Iishiti zentsimbi ezenziwe ngesinyithi ezenziwe nge-electroplating zinokusebenza kakuhle kokusebenza, kodwa ukugquma kuncinci kwaye ukuxhathisa ukubola akulunganga njengaleyo yamaphepha entsimbi aditshiwe ashushu;isixa zinc encanyathiselwe electro galvanized steel coilis incinci kakhulu, kwaye kuphela udonga lombhobho wangaphandle lufakwe igalvanizing, ngelixa i-hot-dip galvanizing ingaphakathi nangaphandle.

Ixesha lokuposa: Nov-17-2023